|

|

It is through science that we prove, but through intuition that we discover.

Jules H. Poincare

The critical importance of corrosion has been known for centuries as have ways

to try and reduce it; for instance the 4th Century Iron Pillar in Delphi (right) is protected by a thin

layer of misawite due to a high level of phosphorus in the cast iron. However, much of our current

knowledge is from the mesoscale down to several nanometers. There has

been an explosion of tools to image materials at the atomic scale, as well as accurately calculate

their behavior. For instance, not only can single atoms be imaged, their chemical state can be

measured. Modern ab-initio methods such as density functional theory are now starting to be

able to handle materials such as transition metal oxides, where older functionals can go wrong.

The critical importance of corrosion has been known for centuries as have ways

to try and reduce it; for instance the 4th Century Iron Pillar in Delphi (right) is protected by a thin

layer of misawite due to a high level of phosphorus in the cast iron. However, much of our current

knowledge is from the mesoscale down to several nanometers. There has

been an explosion of tools to image materials at the atomic scale, as well as accurately calculate

their behavior. For instance, not only can single atoms be imaged, their chemical state can be

measured. Modern ab-initio methods such as density functional theory are now starting to be

able to handle materials such as transition metal oxides, where older functionals can go wrong.

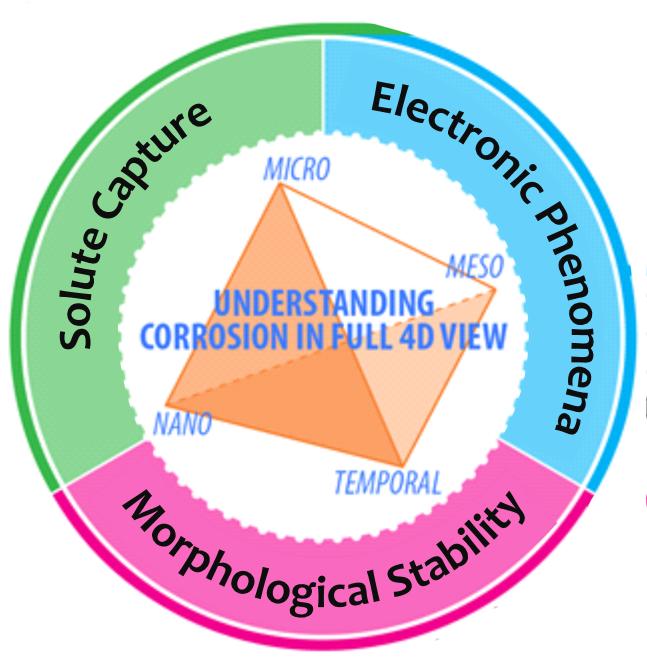

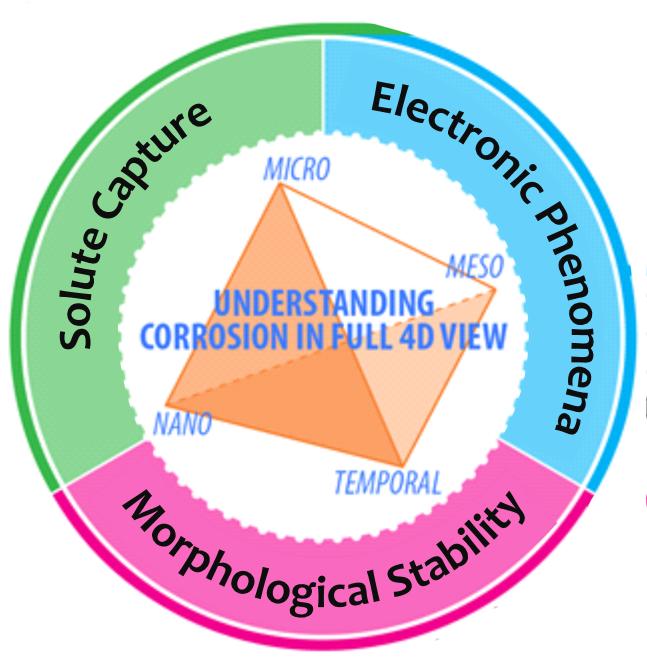

The intent of this Office of Naval Research funded program is to bring the full power of these new tools to bear on corrosion at the atomic scale. However,

a characterization tool by itself does not reveal the full science, we need to go beyond this.

The last decade has seen enormous advances in areas such as designed low-friction coatings to advanced steels and alloys for racing cars.

These achievements depended upon detailed knowledge of how the nanoscale structure influenced the properties in 4D. We hypothesize the same can be

done for high-temperature alloys, by deliberately designing the near-surface selvedge region microstructure at the nano to mesoscale.

We know that the selvedge region, that is the area near the surface where properties are significantly different from the bulk material matters, but we do not

understand the details.

What transient and perhaps metastable oxides form on NiAlCr alloys? Are they the same in the different phases and how do we understand and accurately model this?

Does the temperature dependence of oxygen diffusion lead to MoOx oxides in the bulk material and phase boundaries in the selvedge region, and what are the kinetics?

What is it about dopants in alloys changing aqueous corrosion, is it changes in the Fermi energy of the oxide or do segregation and diffusion also matter?

Our specific target is to understand in detail the early-stage oxidation and aqueous corrosion in three selected model systems. We believe that a comprehensive

experimental and theoretical attack on the details will enable us to understand what matters, what does not, and lay the basis for a paradigm shift in improvements of

corrosion-resistant materials. Our specific targets are:

- NiCrAl alloys, a classic two-phase high-temperature alloy with alumina or chromia protection.

- MoSiB alloys, a new class of alloys for higher-temperature applications with a self-forming glass protective coating

- Aqueous corrosion resistant materials such as Ni-Cr-Mo with dopants effecting oxide growth that are used for many current marine applications.

Beyond these the Team members are involved via other funding in many other areas of corrosion where we are using the same atomic-scale tools to unravel the fundamental

processes, ranging from Corrosion and TriboCorrosion of Orthopedic Implant Materials to Lifetime Predictions in Corrosive Environments.

|

Research Vision

Research Vision

Research Vision

Research Vision